In passenger information displays system, the LCD suppliers such like Risingstar always facing same problem: the display should have suitable size.

Most of the LCD panel has inborn aspect ratio which is 16:9, this ratio also be knows as 1920*1080 full-HD, this aspect ratio is the most closed value to the human eyes viewing range.

Now you get the reason why LCD makers use 16:9 as the standard, it was a trick to make people be immersed while watching the movie, or much comfortable to use the display, but this trick only working when people is in face of the monitor and keep stable, otherwise it looks no differences with displays have different aspect ratio.

Back to the PIDS (Passenger information display system), the aspect ratio of the displays doesn’t decide by LCD makers, train makers do it.

As an extremely complex system, one single train/cabinet probably have hundreds of suppliers, it means multiple standards will apply in one object, also the mechanical structure of the train is fixed, it is impossible to tell the train maker redesign the cabinet worth millions dollar to adapt an LCD display only cost thousands dollar, so we need adapt them.

Risingstar offering multiple sizes of LCD panel or LCD displays to the train makers/metro company from all over the world, and we have ability to double-cut the Liquid crystal glasses to adapt the request from our customers, more details please contact with us.

Sometimes the customer can find the suitable inborn stretched LCD display from LG/BOE/AUO directly, in usually the size they want require the double-cut, here are 3 mainly way for Risingstar to cut the LCD:

Knife wheel cutting:

Knife wheel cutting is also known as mechanical cutting.

Firstly, fix the liquid crystal empty cell prepared in the previous process on the cutting machine worktable, and use the cutting wheel to swipe along the cutting mark on the glass under a certain pressure, forming a consistent depth and width cut on the glass. The accuracy and speed of this equipment directly affect the product quality and production efficiency.

The trajectory of the blade wheel movement is called the cutting line. During the cutting process, each group of LCD screens has a cutting mark on each of the four corners. Due to the exposed electrode surface of the LCD display, the display is divided into upper and lower glass sizes. After confirming the upper and lower pieces, place the glass on the cutting machine platform and fix it. Set the cutting data (including cutting times and step distance, etc.), adjust the cutting depth and pressure of the cutting knife, and make a trial cut at the edge of the glass where there is no pattern. After adjustment, batch cutting can be carried out. The cut glass needs to be broken, which is done by a splitting machine. The principle of splitting is to apply a certain pressure on the back of the glass with cutting knife marks to cause slight deformation of the glass, and the glass will crack along the cutting line. To facilitate the pouring of liquid crystals into the cracked LCD box, the empty box needs to be placed in a dedicated basket. After pouring the liquid crystals, the LCD box strips need to be cut into LCD box units using a cutting machine.

It has cost advantages, wide applications, mature and stable technology, simple process, and high efficiency; The yield of glass cutting mainly depends on the quality of the blade wheel (in terms of performance: stability, sharpness of the cutting edge, precision of processing, adaptability between the blade wheel and the cutting machine, and other high-precision characteristics). The knife wheel has evolved from alloy knife wheels (commonly known as tungsten steel knife wheels) for cutting ordinary flat glass and float glass to ordinary diamond knife wheels, high penetration and micro tooth diamond knife wheels for cutting TFT-LCD panels, substrate glass, and touch screens;

The mechanical cutting method has certain drawbacks for ultra-thin substrate materials. Especially when the cutting tool generates small debris in the material, and the cutting surface is not necessarily perpendicular to the glass surface; In addition, mechanical cutting leaves significant mechanical stress at the edges after processing. In fact, it is very difficult to mechanically cut and process substrate materials with a thickness less than 1mm, as glass of this thickness is very fragile. To prevent further breakage of glass after initial cutting, it may be necessary to grind or polish the cutting surface. Moreover, the subsequent cleaning process is also necessary to remove debris that may interfere with subsequent processes such as circuit formation. Laser cutting of glass solves these limitations.

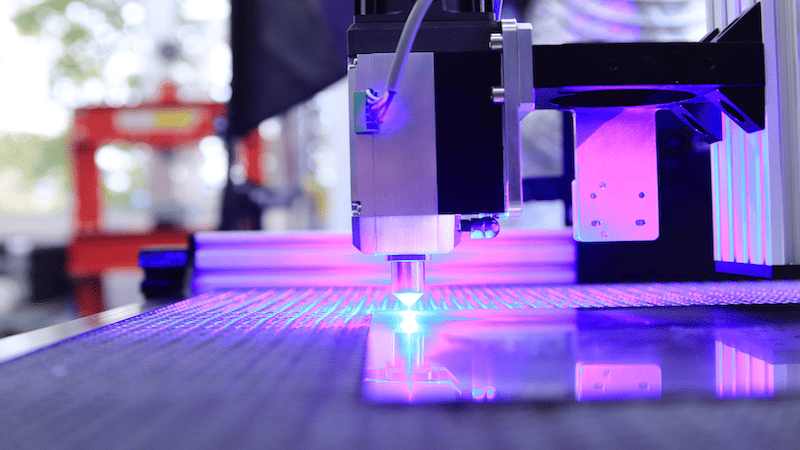

laser cutting:

Laser cutting is the use of a focused high-power density laser beam to irradiate a workpiece, causing the irradiated material to rapidly melt, vaporize, ablate, or reach the ignition point. At the same time, a main, high-speed airflow coaxial with the beam is used to blow away the molten material, thereby achieving the cutting of the workpiece.

Laser cutting of glass substrates is a complex photothermal process and the interaction between laser and materials. This process includes transient thermal conduction caused by the laser moving the heat source to heat the material, thermal stress generated by temperature gradient changes, and the use of thermal stress to induce crack propagation until fracture, thereby segmenting the glass substrate;

Laser cutting of glass substrates is commonly divided into two methods: controlled crack cutting and melt evaporation cutting.

On ultra-thin phones, its thickness is reduced to 0.3mm, and even on larger (60 inch) televisions, a glass panel with a thickness of only 2.8mm has become standard. Anyway, thinner glass is more precise from a mechanical processing perspective. This makes glass more difficult to cut and process in production, and makes the final product highly susceptible to breakage. This requires that the cutting process technology must use laser cutting to achieve.

Laser cutting has the advantages of high precision, high efficiency, and high degree of automation; The non-contact process used in laser cutting completely eliminates the problems of micro cracks and debris. Moreover, laser cutting eliminates residual stress in the glass, resulting in higher edge strength. Laser cutting reduces the number of process steps as it does not require any subsequent cleaning and grinding steps. Although the investment cost of laser cutting is higher than that of mechanical cutting systems, the total investment cost of laser cutting will be lower than that of mechanical processing due to the elimination of grinding equipment.

Water jet cutting:

Water jet cutting is a cold cutting technology. It is further divided into pure water jet cutting (using pure water as the energy carrier, with a simple structure and slow nozzle wear, but poor cutting ability) and abrasive water jet cutting (using water and 90% abrasive as the energy carrier, with strong cutting ability).

Compared with conventional laser and knife wheel cutting, it has unparalleled advantages in composite multi-layer display materials, reinforced glass, etc. due to its non heat source, high energy, and no transverse micro cracks generated during cutting; Advantages of water jet cutting: it will not produce cracks when cutting, it can cut materials with very narrow gaps, can make all-round cutting, including various shapes, angles or slopes, and does not need secondary processing such as edge grinding. It can also reduce flying dust and improve the working environment during the cutting process.

Risingstar Stretched LCD panel:

14.1-inch 4K stretched LCD panel

48.5 inch high brightness stretch LCD panel for passenger information

37 inch high brightness stretch LCD bar for passenger information display