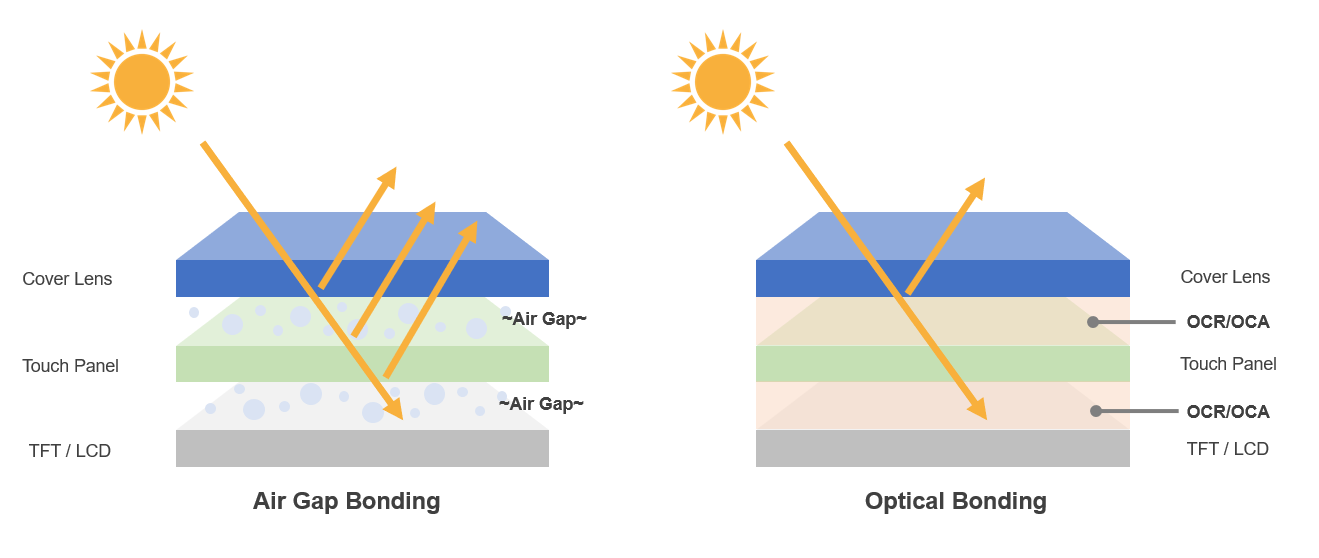

Optical bonding is a special assembly solution compared to general air bonding. It uses a transparent colloid (OCR) to fill the air gap between the glass and the panel. We widely use this solution for three main reasons:

First, optical bonding provides much better stability than air bonding. The colloid adheres to both the tempered glass and the LCD screen, as well as the touch panel if the LCD has touch functionality. By bonding these layers together into a single unit, the LCD can withstand much more severe impacts.

The second advantage is that the colloid fully fills the gaps. Dust, water, and even heat find it difficult to penetrate the glass and damage the LCD screen behind it. Additionally, there are no condensation issues since there is no air inside the gaps.

The final and most important feature for “display” is the ability to reduce light interference. Because the colloid fills the gaps, and the OCR we use as the colloid has a refractive index close to that of the tempered glass and the LCD glass, the separate layers are not only bonded mechanically but also optically.

Without optical bonding, light would be reflected and refracted by each layer of glass, causing what we call glare. With optical bonding, glare still exists, but its effects are reduced due to the fewer reflective surfaces.

Moreover, applying an anti-glare coating to the tempered glass can also reduce light effects. We usually perform both processes on the LCD monitor to ensure it displays the best performance and helps our customers.

Ask a quote for the latest price and one of our team members will respond as soon as possible.