When we talk about "wide temperature" LCDs, we usually focus on high temperatures since sunlight and the working heat from the LCD itself can increase the temperature. When the temperature exceeds the level that can maintain the liquid crystal's properties, the liquid crystals can behave similarly to water turning into vapor, causing the LCD to be easily damaged by overheating and becoming hard to repair.

In fact, at low temperatures, LCDs might be broken for similar reasons. However, the molecular structure of liquid crystals is much more complex and differs greatly from water. You should know that ice has a larger volume than water with the same weight.

Anyway, using the LCD within a suitable temperature range is key to extending its lifespan. But sometimes, even if the environmental temperature is not higher or lower than the working temperature specified, the LCD can still break due to temperature issues.

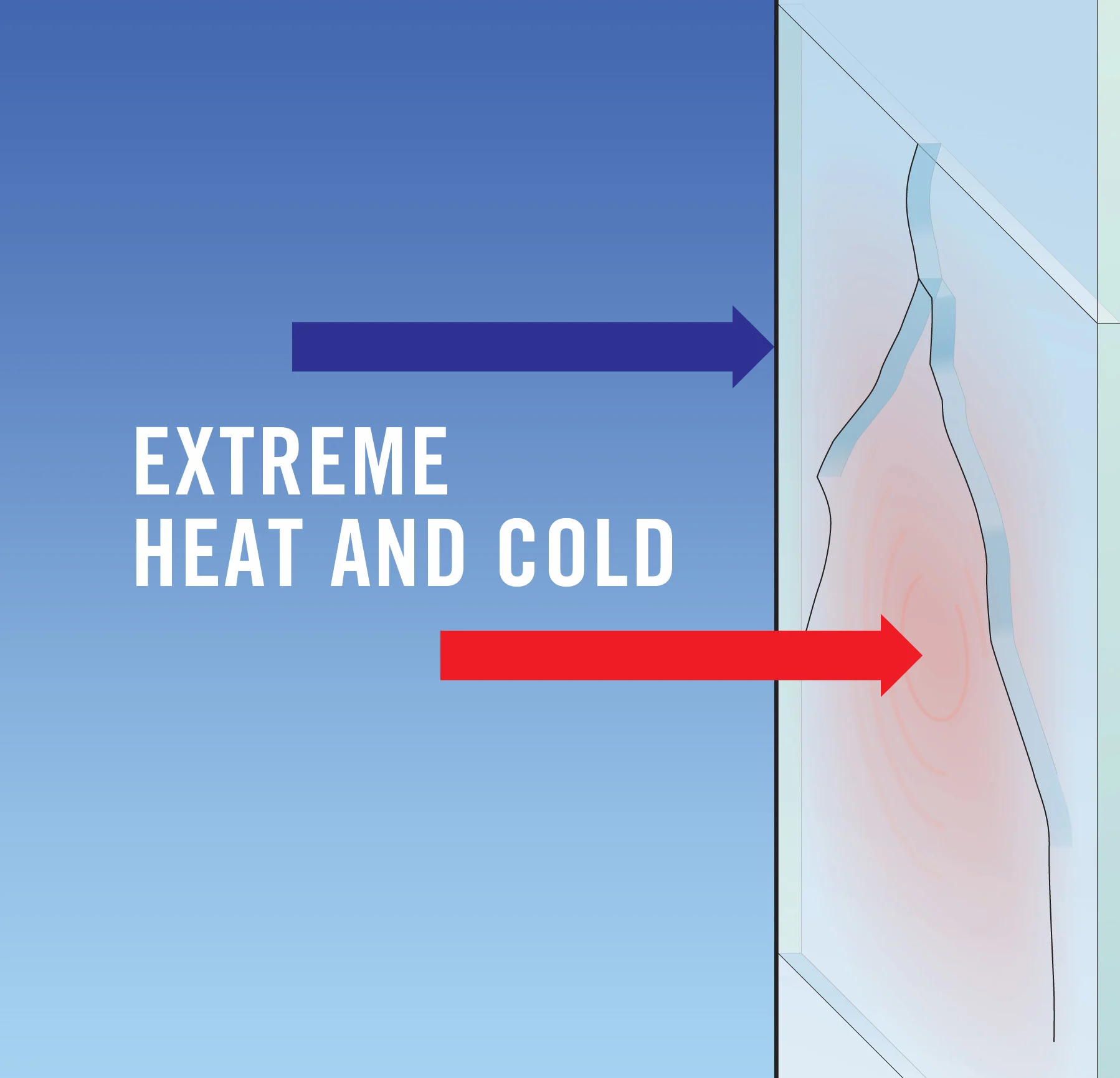

This is because of the temperature changing the substance features. As we mentioned, ice has a larger volume than water with the same weight; liquid crystals and other parts of the LCD have similar properties, expanding or contracting with temperature changes.

The materials used for LCDs contain a lot of glass, which is transparent and allows light to pass through with minimal effects. This includes the cover glass, the LED backlight beads, and the layer we call "open-cell" that locks the liquid crystal, also known as "liquid crystal glass" (which is actually plastic but as vulnerable as real glass).

When part of the glass is heated and expands, while other parts remain stable, the stress difference between them can break the glass, even if the LCD is working within the regular temperature range.

This usually happens in winter when you turn on the LCD and the LED beads generate heat because they are lighting up. Parts of the LCD are heated, but the rest remain at a low temperature, and then the glass part of the LCD can break, maybe even the LED bead itself, rendering the LCD inoperative.

The solution is to heat the entire LCD to a suitable temperature before actually turning it on during winter. This keeps the internal stress balanced, preventing the LCD from being broken by rapid temperature changes.

The problem is that it takes at least 20 minutes to heat up, so we set the automatic turning on for the AC heat, which is 30 minutes earlier than the monitor turning itself on.

This is a mature solution for us and is used in the Scandinavian area to protect our products from working abnormally, ensuring our customers' profits are not affected by this issue.

For more details, please contact us via info@risinglcd.com.

Ask a quote for the latest price and one of our team members will respond as soon as possible.